In previous blog posts, we discussed how to find, analyse and record data from manufacturing issues. In this post, we discuss how we can start to use the previous data collection to: Just Improve It!

Improve your problems

No one likes a problem, right? Even more so when those problems have been costing you money. Let’s find how we can turn fortune around to improve that. We discussed about isolating the key X’s and walking through the steps to understand if these were having an effect upon your Y here:

How To Analyse Problems In Manufacturing Settings?

So now its time to generate potential solutions those proven key X’s. Evaluate solution alternatives and implement the right set of solutions. After all, you don’t want to implement the wrong solution, or implement a solution that looks good on paper here, but you run into larger issues further down the line.

Before implementing the solutions;

To ensure that we don’t walk ourselves into those issues. We need to ensure that a full helicopter view of the new solution is taken. Guess what that means? More process mapping!

Ensure that a full process map is constructed implementing that new or improved solution. Act out an FMEA on that solution, walk the line with it, make sure it’s mistake-proof and then conduct pilot testing on the solution.

Pre-empt issues, and don’t make it harder for yourself than it needs to be. Don’t run before walking, use the pilot process to prove out your issue in an environment that’s isolated from main production areas. There is no need to risk production.

Ensure that at all stages of the above, key stakeholders of the process are involved. This allows for fresh eyes and a sense of accountability to be captured in the process. It will make for an entirely better process implementation if team members believe in the project.

So how do we actually generate those solutions?

- Brainstorming

- Creative thinking techniques:

- Six thinking hats

- Anti-brainstorming- how to make things worse

We make lists, of course, we analyse the lists of solutions and we use our analytical skillsets to ensure these work, or don’t.

Evaluate the solutions

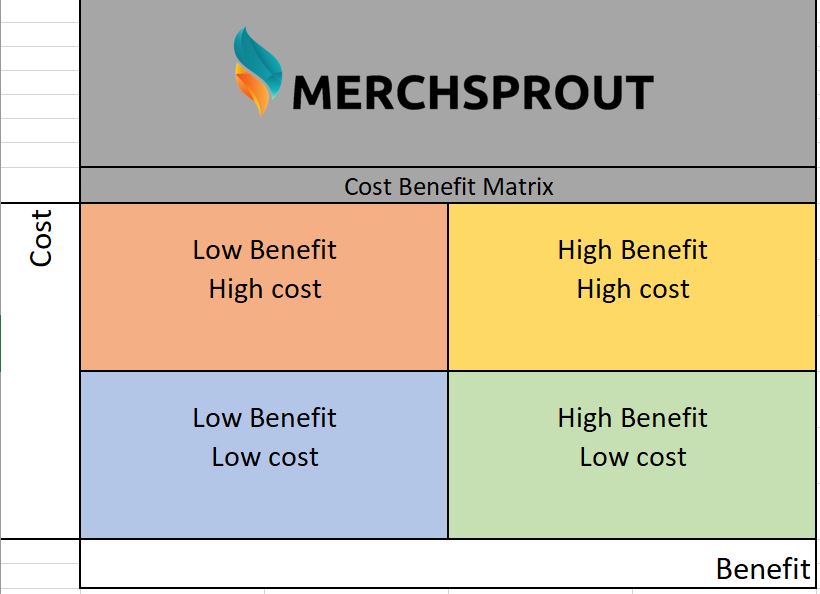

Personally I like to make shortlists here, using 2×2 matrices we can evaluate how hard it is to implement and what is the effect. In essence, we can grasp the low hanging fruit first.

Selecting the solutions

Here again, I like to keep things as simple as possible; by using visual selection matrix’s we can simply and easily visualise the benefits.

Let’s list some of the tools that we use here at Merchsprout.

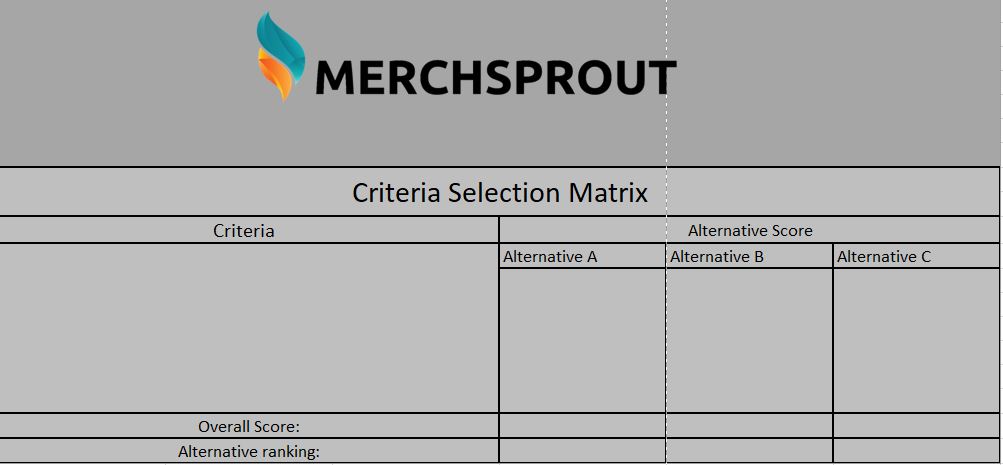

Criteria selection matrix’s are good to score alternative criteria ideas.

To begin completing the matrix, the project team agrees on the criteria. The team brainstorms to generate a list of potential criteria and reaches consensus on the criteria to be scored against.

After consensus is reached, place the criteria items under the criteria column on the matrix.

Rate the alternatives against each of the criteria using a scale of 1 to 5, with 5 being closest to ideal. This can be done by collecting and analysing actual data if it exists or by rating the alternatives subjectively.

Once the scores have been calculated against each of the criteria, multiply them together. The alternative with the greatest score is then selected as the solution that is closest to the ideal criteria.

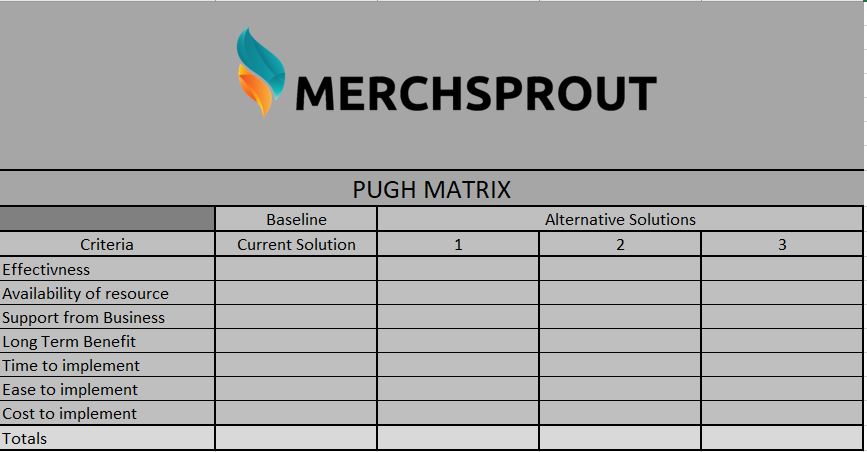

Pugh Matrix is marked using “+”, “–” or “S”.

“+” means a particular solution scores better on a particular criteria as compared to the datum

“–” means a particular solution doesn’t score better on a particular criteria as compared to the datum

“S” means a particular solution scores the same on a particular criteria as compared to the datum

The baseline by default has “S” rating assigned to all its criteria. This is because it is the same as itself and hence has the score 0.

The Pugh Matrix relies on human judgement to subjectively assess the criteria against the baseline.

The scores are aggregated by counting the number of “+” and “–” that a solution has.

The “+” and “–” are then used to compare the final score. If any solution has a score greater than 0 i.e. greater than the baseline, it is considered for selection. If all the scores are less than “0”, then the datum is selected as the final solution.

The cost-benefit is explained above. It’s the matrix we use to grab the low hanging fruits first. Those High benefit low-cost big hitters.

All recommended solutions must be approved by the team before implementation.

FMEA is conducted against all the solutions above and scored. The RPN number (risk priority number) generated from the FMEA can be used to prioritise the failure modes of the solutions and mitigate the risk or discount the solution.

Do not fear, we will go into DMFEA and PMFEA in greater detail in a later blog post. They are great tools to have in your arsenal.

Mistake Proofing

Error proofing is a great way to ensure the problems that we are trying to solve do not introduce more error states into the process. After all if what we are trying to achieve is a refined process that’s more efficient then introducing additional errors is a tad counter-intuitive.

Through our FMEA scores and brainstorming, we ensure that errors are prevented from occurring, and, if not 100% possible to remove the possibility of occurrence we want to reduce the risk as much as possible; if errors do occur systems are required to ensure they are captured immediately.

Mistake proofing has three levels (in order of preference):

- Prevention

- Facilitation

- Detection

Obviously, the most preferred method of error proofing is prevention. However, if prevention of a mistake is not possible 100% of the time then facilitation is required. It is the facilitation of work to minimise errors. A good example here is on a McDonalds cash register, the cash price of products is instead a button. This means that a cashier can just press a button. Hence removing the requirement or possibility for the cashier to know the individual price and get the price wrong.

Of course, the example does not mitigate the cashier pressing the incorrect button.

If this can not be achieved, then we need detection. A good example, that un-surprisingly I use a lot is the spell check in a word document. If spelt incorrectly a big red line pops up underneath.

Pilot testing and implementation of solutions

A pilot is a small scale test to ensure the results of your solution will come out as planned.

We pilot in one location or factory first. A pilot is actually data collection exercise and proves out how well the solutions will work. Will the solutions show any improvement, will there be any issues introduced, if so what are those problems and can they be fixed and solutions revised? What can be then conducted to implement full-scale implementation on the main production line?

Remember:

FAIL to PLAN

PLAN to FAIL

Do You Need Help Finding That Needle In The Haystack?

The only 100% sure-fire way to ensure you are dealing with quality in Chinese factories is to have someone on the ground, on your side. Batting for your team. A team player who not only knows how to capture and report out but a player that can hold those suppliers to account in the event of quality issues.

Here at Merchsprout, we do just that, we offer you the ability to save time and money by doing the hard work for you. We offer several services that allow you to remotely oversee operations.

If you want to learn more about how we do what we do and the services we offer, have a look here.

Source Chinese Products Without Going China

If you want to just get in touch, we are a friendly bunch and honestly just like hearing from you. Contact us, leave a comment or add us on Linked In.

Dealing Remotely Is Very Much A Possibility, Have The Right Team Members On Your Side

Source Chinese Products Without Going to China is not only a possibility it’s relatively easy when you have the right team on your side. We are the right team for Sourcing, Auditing and Quality control.