The Most Valuable Skill In Quality Is Measuring

Everyone Knows What Quality Is Right? … Right?

What is quality?

Really, how can you define quality? We sure know when something is of poor quality: It’s loose, doesn’t operate in the way that it should, or occasionally it doesn’t operate at all. Possibly it fails prematurely or does not operate to our expectations- we class it as of poor quality.

So subsequently you would suggest things of good or exceptional quality behave in the opposite of ways?

Yes, and no.

You see its not as clear cut as that. I will give you a conundrum:

The aeronautical industry has some of the most stringent risk-averse, safety standards of any industry. And with good reason. With 176 thousand individual flights daily; the aviation industry has to ensure the safety of a huge number of people.

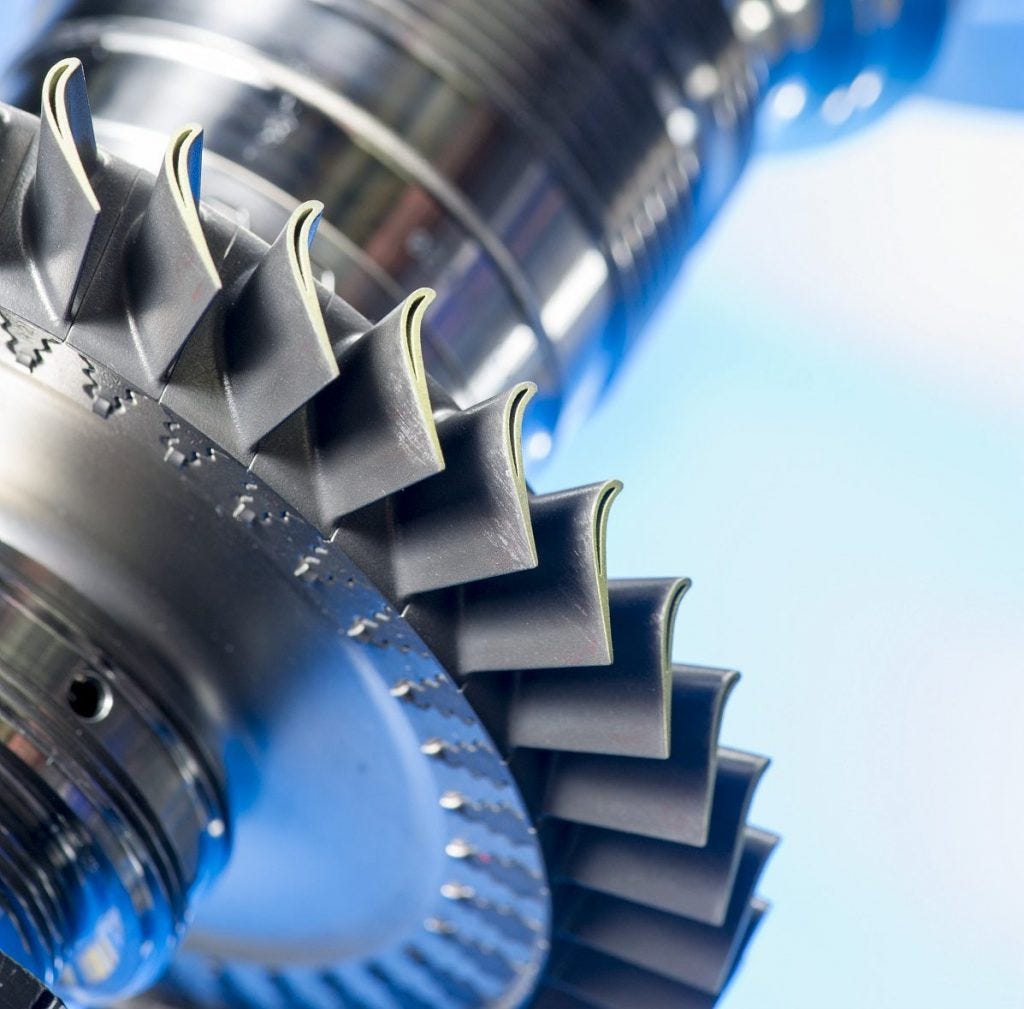

At the centre of the majority of aeronautical travel is the turbine, otherwise known as the engine (to make things simpler).

Plane engines, from an internal perspective, look very complex, and indeed they are, but the fundamentals of the concept are elementary. You have blades, spinning very, very fast, drawing air in through an orifice, injecting fuel into this superheated atmosphere, causing it to combust, and creating thrust by expelling it out of the rear. To produce enough thrust to get a plane weighing almost 440 tonnes (Boing 747) off the ground, you can appreciate those spinning components inside the engines, are travelling extremely quickly; 20,000rpm. To put that in context, your car idles at 900rpm (or even lower) and in the vast majority of cases has a rev limiter of 6000 to 7000rpm.

Ensure Quality

20,000rpm is exponentially faster than your usual internal combustion car engine. Yet the safety standards of the components in an aeroplane setting need to be far more robust, and therefore the components are of a higher quality standard. In fact, the turbine blades; to ensure they don’t break apart under these massive loads are grown out of a single crystal of metal, in a process called the Bridgman method. This removes the slip planes of the structure of metals and you are left with a single blade, grown from a single metal crystal, allowing the turbine to spin at enormous speed and withstand forces of thrusting a 747 to take-off.

You have to admit then these blades must be high quality, and indeed they do look like a beautiful quality piece of engineering.

https://www.aero-mag.com/one-million-turbine-blades-delivered-arconic-safran-hit-major-milestone/

But here is the conundrum;

You would not use a turbine blade as a chair to sit on (OK, bear with me here) would you?

Well, no of course not, because that’s stupid? Why for one would you want to use the turbine blade as a chair, and secondly, a quick slip on the blade and it may end up being a harrowing, strange trip to the hospital.

But that doesn’t mean that the turbine blade is of poor quality because it doesn’t function as a chair?

And here we have a strange understanding of quality.

Quality is a direct function of the tests that a component has to pass to be able to be called a component of high quality. If for example, we were able to mould a cheese into a turbine shape and run it in an engine, well of course, with the temperature and pressures inside an engine, the cheese would melt (great fondu environment though).

Yet, because it melted; would this mean it was of poor quality? It was definitely not the correct material to use for a turbine blade, so in that respect, it was poor quality. Still, like a cheese, maybe it was an excellent Swiss Gruyere, which for all intense and purposes is a wonderful, quality cheese.

Swiss Gruyere, which for all intense and purposes is a wonderful, quality cheese.

It’s important to know what we are actually measuring, what the conditions are in the environment the product is operating in and the constraints of the materials used in that specific example.

Which is why its extremely important, when designing a component that needs to be of very high quality; we need to know not just how to measure the environment it’s going to be operating within, but how to ensure that during testing, we measure the correct areas of the test piece. This ensures we are testing as accurately as possible, proving against our testing standard, it’s going to work for as long as required, in the range of operating parameters.

You could almost say, there are no instances of components of good quality.

There are just components that work; as they should, in the environments they were defined to be in. And this is because the measurements taken when designing the test specification were well documented and understood.

Hence, the most important skill in quality is not the measurement of quality itself. More, a measurement of the requirements of the component, giving the component a level of quality that is acceptable for the environment it’s used in for the correct period of time.

Sign up to my Engineering Newsletter Here.