Plastic injection molding

A cornerstone of modern manufacturing, boasts a rich history rooted in the 19th century. Emerging as a solution to the unsustainable use of ivory for billiard balls, this innovative process has undergone a remarkable evolution, shaping the landscape of production as we know it today.

The Billiard Ball Dilemma

In the 19th century, billiards was a popular pastime, and the balls used for the game were crafted from ivory sourced from the tusks of African elephants. However, as concerns about the declining elephant population grew, so did the need for an alternative material for billiard balls.

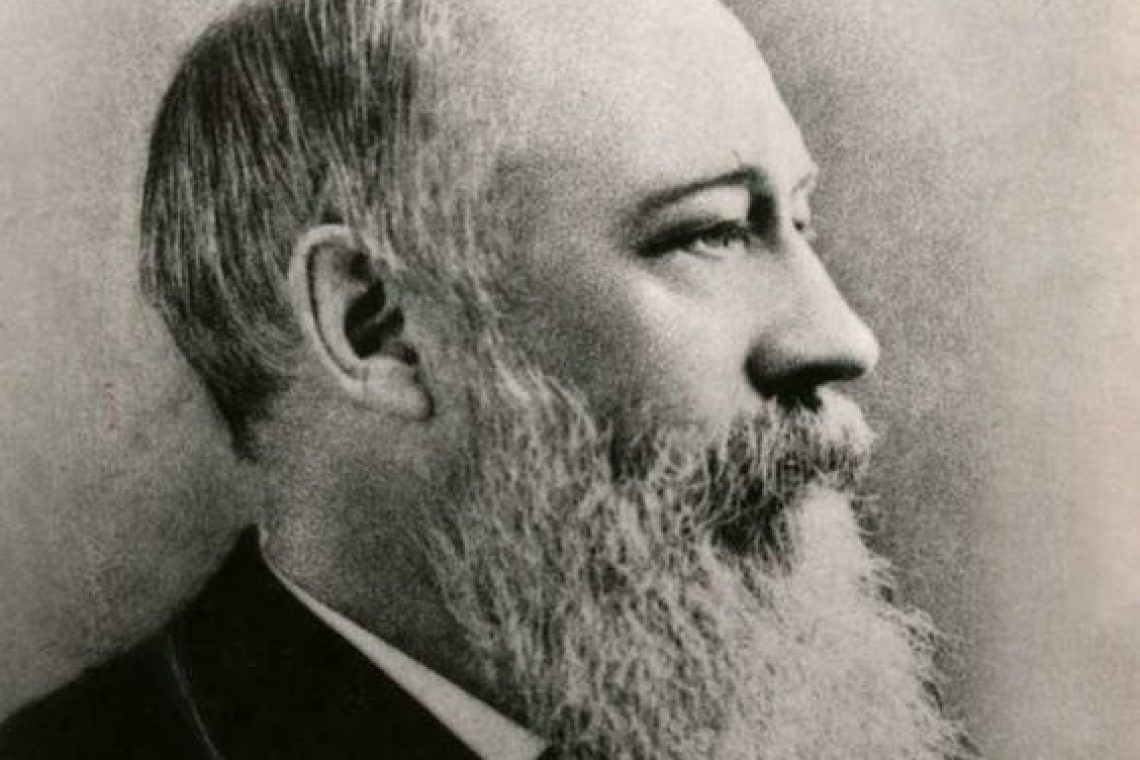

John Wesley Hyatt’s Inventive Breakthrough

In 1872, John Wesley Hyatt, an American inventor, provided a groundbreaking solution to the billiard ball predicament. He introduced a plastic injection molding machine that utilized celluloid material, marking a significant departure from traditional manufacturing methods.

Celluloid, a revolutionary material for its time, was injected into a mold to form billiard balls. Hyatt’s invention not only addressed the environmental concerns associated with ivory but also paved the way for a new era in manufacturing.

The Birth of Plastic Injection Molding

Hyatt’s plastic injection molding machine operated by forcing molten celluloid material into a mold, where it solidified to create the desired shape. Despite the initial success, the early iterations faced challenges. Controlling the plastic’s temperature proved difficult, leading to inconsistencies in material consistency and temperature during injection.

Evolution Through Challenges

Recognizing the potential of plastic injection molding, innovators continued to refine the process. By 1946, the technology had undergone significant improvements. The modern plastic injection molding machine, as we recognize it today, had taken shape, featuring a screw mechanism and heating bands as opposed to Hyatt’s piston-based approach.

This design innovation brought about a more uniform heating process, ensuring consistent material quality and temperature control during injection. The fundamental principles laid down by Hyatt persisted, but the refinements in the mid-20th century laid the foundation for the advanced injection molding machines used in contemporary manufacturing.

Injection Molding Today: A Technological Marvel

Today, plastic injection molding is a sophisticated and highly efficient manufacturing process, integral to the production of a vast array of products. The process involves the use of thermoplastics or thermosetting plastics, which are heated, mixed, and injected into molds to create intricate shapes and components.

Injection molding machines are equipped with intricate systems for precise temperature control, ensuring uniform material distribution and minimizing defects. The versatility of injection molding is evident in its application across diverse industries, from automotive and electronics to consumer goods.

Conclusion: A Legacy of Innovation

The history of plastic injection molding is a testament to human ingenuity and the pursuit of sustainable manufacturing solutions. From its humble beginnings as a response to the ivory crisis in billiard balls to its present-day status as a pillar of modern production, plastic injection molding has come a long way.

As technology continues to advance, injection molding remains at the forefront of innovation, constantly adapting to new materials, design complexities, and environmental considerations. The journey from John Wesley Hyatt’s celluloid invention to today’s state-of-the-art injection molding machines reflects not just a technological evolution but also a commitment to shaping a more sustainable and efficient manufacturing future.