Reducing Production Issues To Make A Profit:

When manufacturing in China as a start-up how to ensure quality learning is robustly fed back into your product design standards

Quality need not be a dark art of smoke and mirrors. It’s not out of reach for anyone in manufacturing environments to reduce quality defects to a near perfection state.

Through methodical process control, you can boost your production quality into outer space.

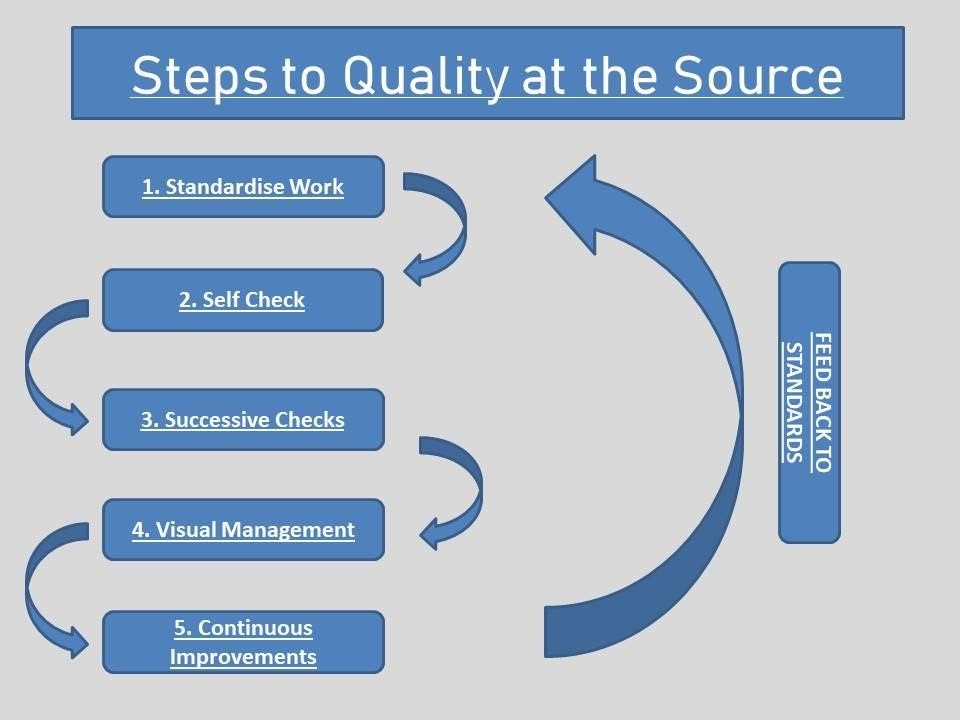

The first step is ensuring your quality feedback operation is a closed-loop system.

What is a closed-loop feedback system?

A closed-loop system

Where the inputs into the first process are taken from the outputs of the last process.

We look to the right-hand side of the process flow on the above chart, it describes feedback, to standards, from the output of a production line process. This simple step is the most important aspect of quality control.

Its something that even the big players of manufacturers struggle with. Only through methodical process control, adequate product quality can be achieved. Every success before then was a combination of luck.

Success in this area is ensuring we feedback the issues into the product using standards derived from data gathered from the product.

Failure to adhere to this simple process will put you head to head with the single, most infuriating of issues in manufacturing:

Repeat failures

Failures that we see time and time again, failures that we talk about, see, have in our hands, look to have fixed, but keep re-appearing.

The most embarrassing of failures, and trust me when I say; can leave you looking very red-faced when facing senior management and investors.

How can we gain these feedback points? It’s one of the key facts taught in Six Sigma.

Manage By Fact And Reduce Variation:

Let’s say we have a production line, a signed-off product and we are starting to produce samples.

If like many, you are manufacturing in China, it’s imperative to have a representative from your organisation in the manufacturing facility at this point. It simply cannot be managed remotely at this stage.

Initial batches of components should be assessed closely, any flaws or production issues noted in documentation to be referenced by both company and supplier. Both need to agree on improvements in processes and product to improve end results.

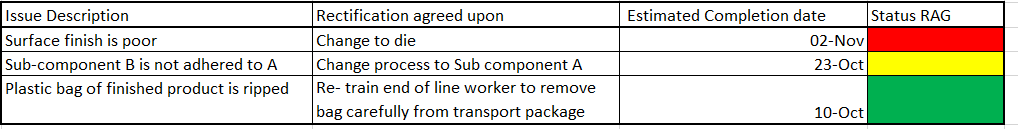

An example of how to record these issues is within an end of line document, it can be a simple excel sheet:

It allows both your company and the supplier to ensure that each item is agreed upon and is rectified. Above is a minimal example of a RAG (Red, Amber, Green) chart that can be generated into a Pareto looking at overall project health. You can also look at implementing KPI’s in at this point. Ensure that each one of these points is agreed upon together in an initial agreement and signed off.

Ensure that you or your agent is in regular touch with the supplier to assure that each of these points is rectified promptly and to a satisfactory standard.

Standards Tracking:

It is at this point that you ensure that you start to complete a standards document. Let’s use the above example as a case study:

Surface finish is poor:

This could be caused by several issues, be it mould issues or other external factors such as material selection etc.

Let’s say for example the incorrect dye has been used in the raw plastic and has had an adverse reaction with the plastic in the mould and has caused an issue with the surface finish of the material. We would first need to ensure that we root cause why this has happened, rectify the issue, run the line to ensure it has been robustly fixed and then:

We would need to ensure that this is referenced in a database of standards to ensure that this type of dye is no longer used again with this material.

As you can probably appreciate, this is a tedious, time-consuming process, with the number of document line items and subsequent standard documents potentially being produced running into the thousands if you have complex components being produced of a complicated line. However, it will be sizably reduced based on the complexity of the product.

Production lessons learned

Should not be underestimated. If you start to produce detailed standardisation document databases that have proven track records, it can be as valuable, if not more, then the product itself.

Hacking Quality Systems:

When approaching quality, the entire sector is a minefield. With so much resource and money being poured into a segment, and rightly so, when quality is improved. Waste is reduced. Meaning that profits can be increased.

When you have an industry that has the potential to attract so much profit understandably, the system will be saturated with terminology that seems gobbledygook to the average person. I draw comparisons to the sports, fitness and health industry; the number of books, terminology with different systems that you can employ to, fundamentally, lose weight, seemingly endless.

It all boils down to a simple system; eat less, exercise more, and you will see the results.

Quality, it’s the same; rubbish in rubbish out.

If we have poor standards and inadequate quality process in the beginning, then we will have a poor product at the end…

RUBBISH IN RUBBISH OUT.

Processes require inputs (x) producing through the process; outputs (y). If you control the inputs, you will control the outputs. This is generally expressed as y = f(x). The f being the factors that affect the inputs and process.

This is one of the key principles of Six Sigma:

The Lean Six Sigma principles are a great way to start to look at the end of the line product to distinguish if the product is satisfactory enough to sign off.

Focus on the customer

- Identify and understand how the work gets done (the value stream)

- Manage, improve and smooth the process flow

- Remove Non-Value-Added steps and waste.

- Manage by fact and reduce variation

- Involve and equip the people in the process

- Undertake improvement activity in a systematic way

I will not delve into six sigma in this blog post. Still, just from reading the above points, you can start to think about how to hack your process when sourcing, manufacturing and conducting quality assurance in China and how to improve your product, process and fundamentally your profits.

There are a lot of people promising immediate results from some far fangled star-studded system, at a cost. There is no easy fix to quality systems; it’s about hard work, finding those root causes and feedbacking them into your standards.

Inspecting The Current Production Quality To Improve Your Product:

We can utilize the supplier’s current components to benchmark against the wanted quality of our product. Ask to see a range of their stock of components they currently make. Inspect them like they would be your product, ask questions about them, ask what material they are using, if the processes the same, is the mould material the same, any questions to build up an understanding of the capability of the manufacturer.

As an example; your supplier produces injection moulded plastic components; using the samples or production runs of the supplier’s current components, you can get to build up an understanding of their current capability.

I advise at this point to inspect items that are straight off the line, suppliers sometimes can offer samples, occasionally these are not a true representation of the capability of the supplier, they can be chosen as the best products, or they could be made off a different line with a different process.

Inspect the sample see if there are any manufacturing flaws that you can write into your standards and agree upon with the supplier before being in the position yourself.

Let’s use an example of a sharp edge in the production of injection moulded parts:

Sharp Corners general design guidelines in injection moulding suggest that corner radii should be at least one-half the wall thickness.

It is advised to avoid sharp corners and uses generous fillets and radii whenever needed. During injection moulding, the molten plastic has to navigate turns and corners.

Rounded corners will ease plastic flow, so designers and tool manufacturers should generously radius the corners of all parts. In contrast, sharp inside corners result in moulded-in stress, particularly during the cooling process when the top of the part shrinks and the material pulls against the corners.

The first rule of plastic design preferably should be that uniform wall thickness will be adopted. As the plastic goes around a well-proportioned edge, it will not be subjected to area increases and abrupt changes in direction. Cavity packing pressure stays consistent.

Leading to a strong, dimensionally stable corner that will resist post-mould shrinkage.

Therefore ensuring that the above learning is taken from the current product and written into our manufacturing standard.

The rule being:

Avoid sharp edges by ensuring each radius should be at least one-half of the wall thickness, and in subsequent design sign off of the component is reviewed for wall thickness and radii to ensure that all aspects of the design adhere to the standard.

This is how a robust, decent quality product is produced. I have used a manufacturing example as the data point generation to feed into the construction of the standard. But in reality, there are many data sets that you can use to construct standards to reduce unwanted production variability.

Cha bu duo:

You may notice (from the above example) that you have found a product with a sharp edge, you measure the component and its radii in the area of question and find it to be of a measurement radius of only one wall thickness thick.

You may approach the supplier who will advise, ‘ahhh Cha Bu Duo’; almost there. You need to ensure that you get across that the standards that are being produced are imperative to the end product.

Get them to sign into the standards, and don’t be afraid to issue warnings to them stating that you will not be paying for these components that fail these standards. Be respectful but firm, ensure that someone is taking minutes at each meeting so no disagreements can be had at a later stage.

Follow us for more Start-up engineering and manufacturing articles. Follow us at merchsprout.com and sign up for our weekly newsletter to get China sourcing tips and tricks.