Quality Control Inspection

Quality control inspection on components

Quality Control Inspection in China

In the pursuit of manufacturing cost reductions through outsourcing processes or goods, conducting a Quality Control Inspection is more than just a box ticking exercise—it represents a critical, hands-on process that forms the backbone of ensuring customer satisfaction and driving business success.

In today’s global market, sourcing products from China has become a norm for many businesses seeking cost-effective solutions without compromising quality. However, distance, cultural differences, and communication barriers often pose significant challenges, and conducting Quality Control Inspections, with real engineers in the factory, is an indispensable process in bridging the gap between expectation and reality.

MerchSprout, with its strategic foothold in both the UK and China, stands at the forefront of this crucial service. We don’t just offer quality control inspections; we redefine them. By integrating expert engineers directly into the heart of the manufacturing process in China, and managing operations with the precision and understanding that only a local presence in both the UK and China can offer, we ensure that the products you source meet not only your expectations but also the highest standards of quality and excellence.

Real World Test Examples of Quality Control Inspections In China

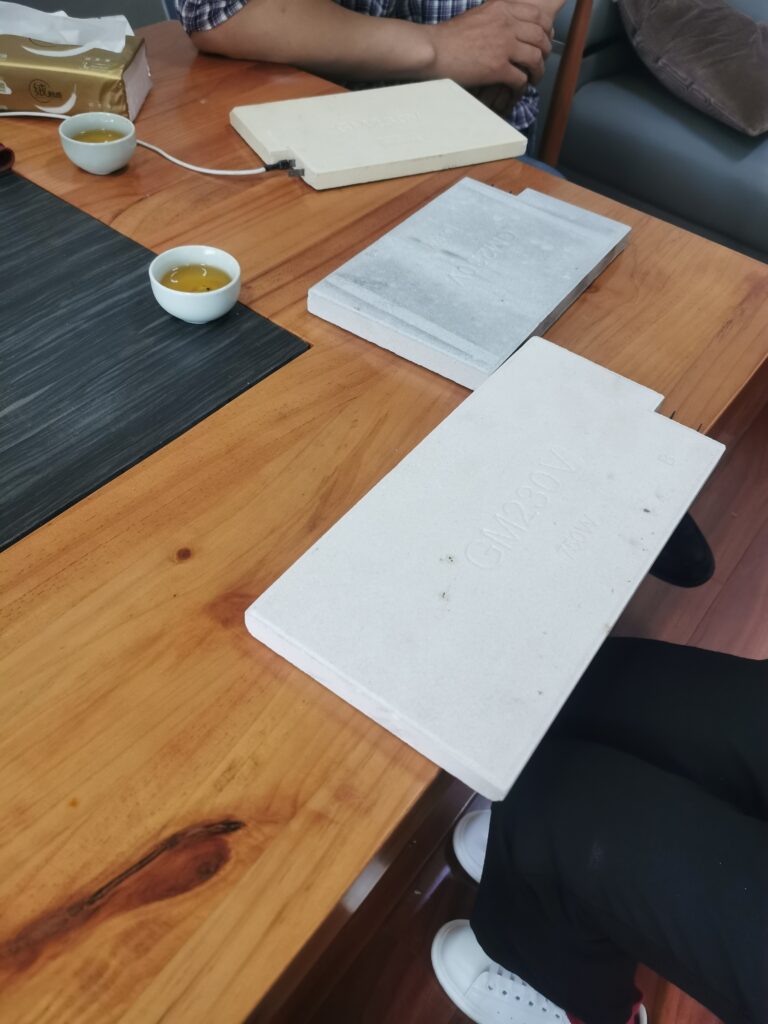

CMM Dimension Tests

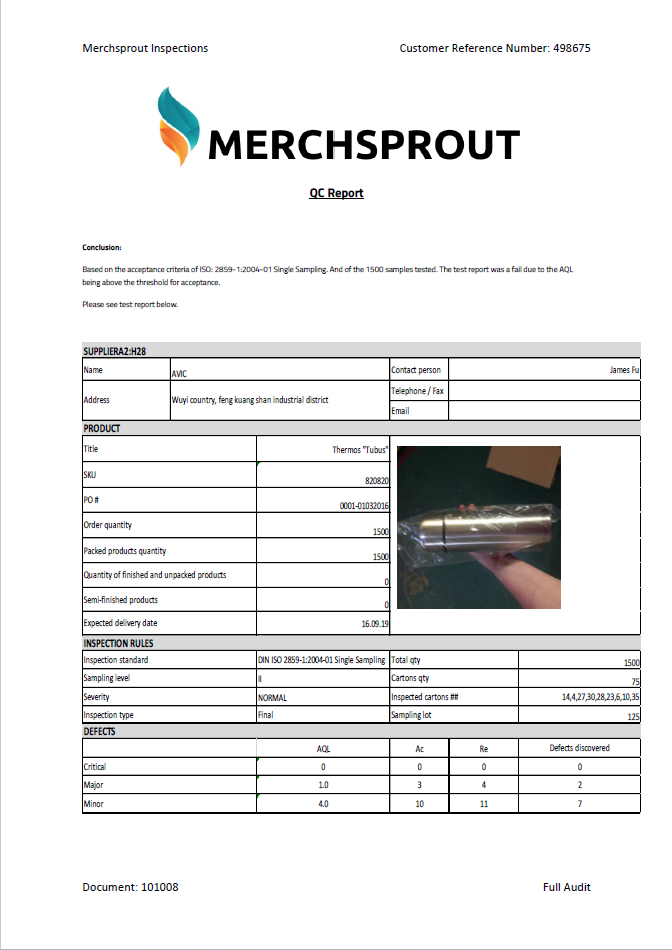

In line with our commitment to quality, we’ve integrated the ISO 2859-1 standard into our inspection process, as demonstrated in our video. An operator employs a Coordinate Measuring Machine (CMM) to ensure each component meets these exacting standards. This practice, part of our routine quality control, involves precise measurement and real-time data analysis, reflecting our dedication to manufacturing excellence.

Battery Cell Testing

The image depicts a vast collection of battery cells at a factory, subject to our meticulous inspection and testing services. We cross-reference each battery against stringent standards such as BS7671, IEC62485-5 for safety, UN38.3 for transportation, and BS EN 62619 for operation, among others, to ensure they meet the highest benchmarks of quality and safety. Our expertise guarantees that these cells, critical for energy solutions, align with international compliance and performance criteria.

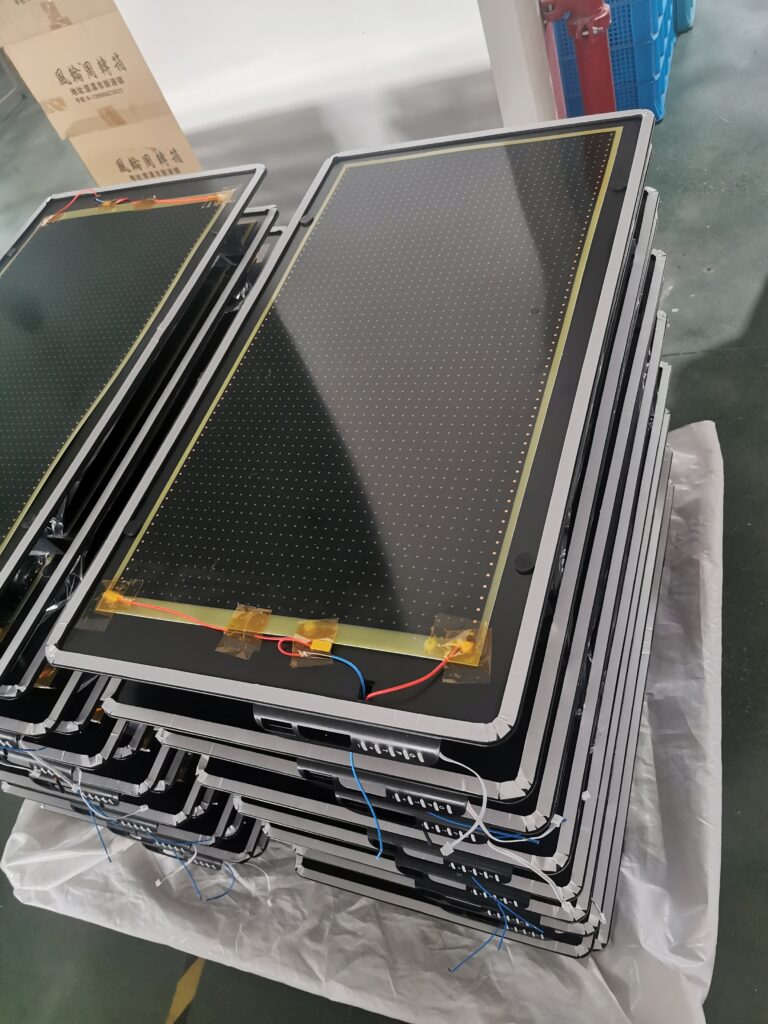

Infra Red Panel Heater Testing

Testing the internal components of an Infra red electric heater prior to container loading and shipping.

The Importance of Quality Control Inspections in China

In an era where global supply chains dominate, the significance of conducting an in-depth, comprehensive Quality Control Inspection in Chinese manufacturing facilities cannot be overstated. China, known as the “world’s factory,” is a powerhouse of manufacturing, offering unparalleled opportunities for businesses seeking to expand their product lines while keeping costs manageable. However, this vast potential comes with its own set of challenges, which is where the critical role of quality control inspections becomes evident.

One of the fundamental issues in overseas manufacturing is the variance in quality standards. What is considered acceptable quality in one part of the world might not satisfy the criteria in another. This is particularly true in the Western markets where consumers demand high-quality products. Quality Control Inspections act as a vital bridge, the eyes on the ground, ensuring that the products manufactured in China meet the stringent quality standards expected by your customers.

Pre-container loading Inspection

Tofu Cat Litter Quality Control Inspection

Independent test lab testing

Moreover, the plethora of complexities of overseeing production processes thousands of miles away can not be understated. Language barriers, cultural differences, and different operational protocols can lead to misunderstandings and errors. Quality Control Inspections serve as a crucial checkpoint, identifying, highlighting and addressing these issues before they escalate into costly mistakes. By having a dedicated team on the ground, and conducting thorough inspections and audits, businesses can maintain control over the manufacturing process, despite the geographical distances.

Another pivotal aspect is compliance with international and local regulations. Quality Control Inspections ensure that products are not only of high quality but also adhere to the necessary safety and regulatory standards, which vary widely from country to country. This is especially important in industries like electronics, toys, and food products, where non-compliance can have serious legal and financial repercussions.

Quality Control Inspections in China are not just a process to tick a box- they are a strategic necessity that safeguards businesses against the risks associated with global manufacturing. It ensures that the final products reflect the quality, safety, and compliance that your customers expect and deserve.

MerchSprout’s Unique Approach to Quality Control

At the heart of our approach to conducting Quality Control Inspections lies a distinctive blend of expertise and strategic positioning. As a company staffed with automotive-trained quality engineers, we bring a level of precision and excellence that is paramount in the automotive industry – known for its stringent quality standards – to all our quality control processes. This expertise sets us apart, ensuring that every inspection is more than just a routine check; it’s a comprehensive quality assurance process.

What truly differentiates our approach is our dual presence, with offices and permanent employees in both the UK and China. This unique setup allows us to offer unparalleled advantages:

Expertise in Both Local and International Standards: Our teams in the UK and China are not just versed in global best practices but are also deeply familiar with local manufacturing nuances. This dual knowledge base ensures that the ‘Quality Control Inspections’ are conducted with a clear understanding of both the source and the destination market requirements.

Real-Time Communication and Swift Problem-Solving: Having permanent staff in both locations facilitates immediate communication across different time zones, enabling quick decision-making and prompt resolution of any issues that arise during the manufacturing process.

Cultural and Linguistic Advantage: Our teams are equipped to navigate the cultural and linguistic landscape of China, which is crucial for effective communication and negotiation. This leads to smoother interactions with Chinese manufacturers and more efficient quality control processes.

Consistent Quality Across Borders: Our automotive-trained quality engineers apply the same rigorous standards in both the UK and China, ensuring consistency in the quality of products regardless of their manufacturing location. This consistency is key to building and maintaining customer trust and satisfaction.

Streamlined Logistics and Oversight: With a permanent presence in both countries, we streamline the logistics involved in quality control inspections. Our teams can easily travel to different manufacturing sites in China, providing on-the-ground oversight and ensuring that inspections are carried out thoroughly and efficiently.

In essence, our approach to ‘Quality Control Inspection’ is more than just a service – it’s a comprehensive solution tailored to the unique needs of businesses navigating the complexities of international manufacturing. By combining our automotive industry precision with our strategic UK-China presence, we bridge the gap between different manufacturing realms, delivering a level of quality control that is both exceptional and reliable.

MerchSprout's China experiences merged automotive quality with the ability to robustly source

Our founder, George, worked in Jaguar Land Rover in the UK and China as senior manager for powertrain quality for the APAC region. Ensuring customer quality was at the forefront of every product implementation.

Now teaching others how to implement the same quality mindset and sourcing items robustly and at repeatable quality from China is the key mission of MerchSprout.

Success Stories and Case Studies

One of the most compelling examples of the impact of our Quality Control Inspection services can be seen in our partnership with a renowned company specializing in electrical heaters. This client’s journey underscores the effectiveness and necessity of thorough inspections in the manufacturing process.

Case Study: Enhancing Efficiency in Electrical Heater Manufacturing

Our client, a leader in the production of electrical heaters in the UK, faced challenges with the quality and consistency of a component in their internal heating units, a critical component in their products. Seeking to optimize their manufacturing process and reduce costs, they turned to us for a solution.

We embarked on a mission to outsource the production of these components, meticulously selecting a manufacturer in China that met our stringent criteria. The real game-changer, however, was our rigorous Quality Control Inspection process.

Our team of expert engineers, with their deep understanding of the standards required for high-quality electrical components, conducted extensive on-site inspections at the manufacturing facility in China. These inspections were not just about ensuring compliance with technical specifications; they were about guaranteeing the durability, safety, and efficiency of the components.

The results were remarkable. Through our targeted approach and continuous quality monitoring, we were able to ensure that each batch of components met the highest standards. This not only led to a significant improvement in the quality and reliability of our client’s electrical heaters but also resulted in substantial cost savings. Annually, the client saved over £200,000, a testament to the effectiveness of our Quality Control Inspection and Sourcing services.

This case study is a prime example of how our comprehensive inspection process doesn’t just identify and rectify issues but also adds significant value to our client’s products and bottom line. By ensuring that every component meets the highest standards, we help our clients maintain their reputation for quality, enhance customer satisfaction, and achieve remarkable cost efficiencies.

As we continue to forge new partnerships and expand our services, this success story stands as a clear indicator of the transformative power of effective Quality Control Inspections in the global manufacturing landscape.

Case Study: Transforming Pressed Steel Frame Production for a UK Manufacturer

Background:

Our next success story involves a prominent UK-based manufacturer specializing in stamped steel products. Historically, they produced their pressed steel frames in-house within the UK. However, to enhance efficiency and reduce costs, they sought our expertise to migrate production to one of our partner factories in China.

Challenge:

The primary challenge was ensuring that the quality of the pressed steel frames produced in China matched, if not exceeded, the standards of their UK manufacturing. The transition also required seamless integration into their existing supply chain without disrupting their production schedules or compromising product quality.

Solution:

Our approach was multifaceted. We began by selecting a factory in China that met our stringent quality criteria. To ensure a robust quality control process, we stationed a full-time representative at the factory. This representative was responsible for overseeing every aspect of production, from material selection to the final product, ensuring adherence to the client’s specific requirements.

We implemented a comprehensive ‘Quality Control Inspection’ plan. This plan involved regular, detailed inspections at each stage of the manufacturing process, enabling us to identify and address any potential issues proactively. Our on-the-ground presence allowed for real-time communication and quick decision-making, essential for maintaining high standards of quality.

Impact:

The results of this strategic move were significant. By transitioning the production of pressed steel frames to China, we achieved considerable cost savings for our client. These savings were not only due to the lower manufacturing costs in China but also because of the increased efficiency brought about by our stringent quality control measures.

The cost savings had a ripple effect on the client’s overall business strategy. Freed from the higher costs of in-house production, they were able to reallocate resources towards marketing efforts. This strategic reinvestment resulted in a remarkable 23% increase in their sales figures, showcasing a direct correlation between effective cost management and business growth.

Conclusion:

This case study exemplifies how our Quality Control Inspection services can play a pivotal role in not just maintaining, but enhancing the quality of products while reducing manufacturing costs. By facilitating a successful transition of production from the UK to China, we helped our client achieve a competitive edge in their market, leading to tangible business growth and enhanced profitability.

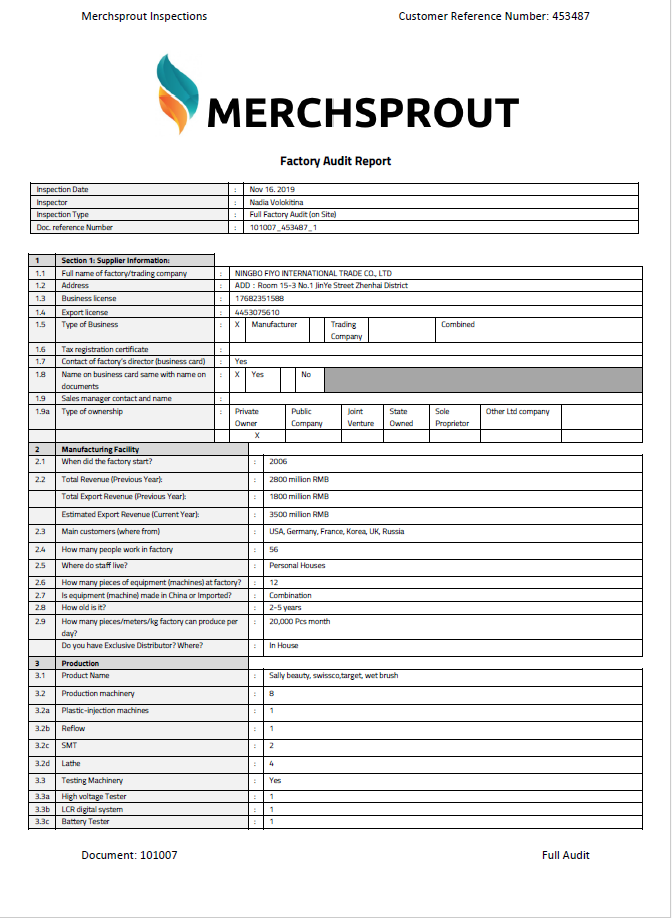

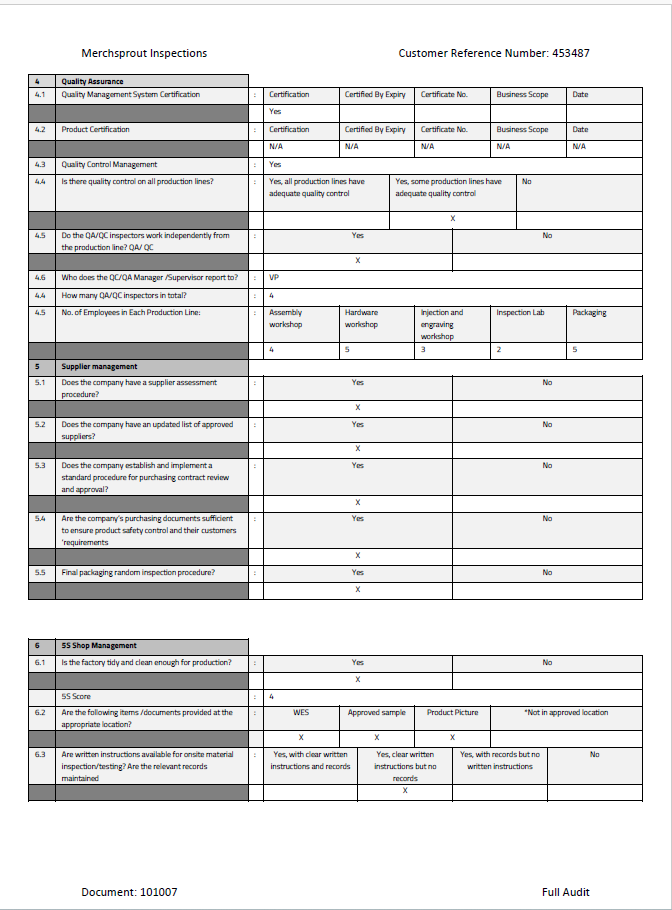

The Detailed Process of Quality Control Inspection

In the realm of global manufacturing, ‘Quality Control Inspection’ is not just a phase in the production process; it’s a comprehensive, meticulous journey ensuring that every product meets the highest standards of quality and safety. Let’s walk through a typical Quality Control Inspection process to understand its depth, thoroughness, and the expertise it entails.

1. Pre-Production Inspection:

The Quality Control Inspection journey begins even before a single unit of product is manufactured. Our engineers conduct a thorough inspection of raw materials and components to ensure they meet the specified standards. This preemptive scrutiny helps in averting potential issues that could arise during the manufacturing process. We also conduct pre-production inspections on manufacturing facilities, inspecting their ability to make the products to our specifications and ensuring working practices are ethical and transparent.

2. During Production Inspection:

As the manufacturing process commences, our on-site engineers perform regular inspections, often referred to as DUPRO (During Production Inspection). This stage is crucial for identifying any deviations early in the production cycle. It allows for immediate corrective actions, ensuring that the manufacturing process stays aligned with the desired quality standards.

3. Post-Production Inspection:

Once the production is complete, a detailed Quality Control Inspection is conducted on the finished products. This phase involves a series of checks, including visual inspection, functional testing, and compliance verification with international standards. It’s at this stage that the product’s readiness for the market is thoroughly assessed.

4. Container Loading Inspection:

Our commitment to quality extends to ensuring that the products are safely and correctly loaded for shipment. The ‘Quality Control Inspection’ at this phase verifies the container’s condition, the loading process, and the correct quantity and packaging, safeguarding the product’s integrity until it reaches its destination.

5. Constant Communication and Reporting:

Throughout each phase of the ‘Quality Control Inspection’, constant communication is maintained with our clients. Detailed reports, complete with photographs, test results, and expert analyses, are provided, ensuring transparency and client involvement in every step of the process.

6. Expertise and Standards:

Our ‘Quality Control Inspection’ team comprises highly trained engineers with specialized knowledge in various manufacturing sectors. Their expertise is not just in identifying flaws but in understanding the nuances of each product, its intended use, and the standards it must adhere to, be they regional or international.

Contact Us

Benefits of Quality Control for Businesses Sourcing from China

When businesses opt to source their products from China, the importance of implementing robust ‘Quality Control Inspection’ services becomes paramount. This critical step in the sourcing process brings a multitude of benefits, both immediate and long-term.

Direct Benefits of Quality Control:

Risk Reduction: ‘Quality Control Inspection’ significantly mitigates the risks associated with overseas manufacturing. By detecting defects and non-compliance early, businesses can avoid costly recalls, customer dissatisfaction, and potential legal issues. This proactive approach ensures that only products meeting the predefined standards reach the market.

Compliance with Standards: Adherence to regional and international standards is non-negotiable in today’s global market. Quality control inspections ensure that all products comply with relevant standards and regulations, avoiding the pitfalls of non-compliance, like fines and import bans.

Peace of Mind: Knowing that each product undergoes a rigorous ‘Quality Control Inspection’ process provides businesses with peace of mind. This assurance comes from the confidence that their products will meet both their specifications and customer expectations, ensuring brand integrity and reputation.

Long-Term Benefits:

Building Strong Relationships with Suppliers: Consistent ‘Quality Control Inspection’ fosters a culture of quality and reliability, which in turn strengthens the relationship between businesses and their Chinese suppliers. This mutual understanding and respect lead to more efficient production processes, fewer misunderstandings, and a stronger supply chain.

Enhancing Product Quality Over Time: Regular quality inspections allow businesses to identify areas for improvement, not just in the products, but in the manufacturing process as well. This continual improvement leads to higher product quality over time, setting a higher industry standard and positioning the business as a leader in its field.

Market Advantage and Customer Trust: By consistently delivering high-quality products, businesses gain a competitive edge in the market. This reliability builds customer trust and loyalty, which are invaluable assets in today’s competitive business environment.