In past posts, we discussed how the “Made in China” stigma is changing or indeed changed. Quality out of China is no longer the product it once was. This was only done through control of manufacturing quality techniques. One of them being the DMAIC tool. But how do we define the problem in manufacturing environments?

Finding the needle in the haystack

When entering a new environment, with so many complex systems interacting, its all to easy to become overwhelmed with the situation.

You have all this noise, people running around, what looks to be harmony in production.

It’s overwhelming. So how do we go about looking for an issue in the midst of all this?

We discussed in previous posts here about DMAIC. The first phase in DMAIC we discussed was, Define. We will go into the definitions stage with greater detail.

Define

We want to get into a position where we are defining the problem and goal statements.

- What is the goal of this project?

- What measurable performance outcome must the project accomplish?

- By when?

By applying the above granularity to a project at the start it allows us to cut through the noise, nail down the if’s and but’s and concentrate on the core questions and outcomes. Excuses are cast aside here, there is no reason to say, yes but, he/ she does this, or cannot do that. This is the phase where the project grows some balls and is kicked off.

Project Charter

The project charter is defined in this stage too. What does that mean?

Getting into the detail of the impacts on the finances and operation. What will it improve in the process and what financial rewards will be achieved?

In the charter, we also develop the team. Who the key players are and who can help and assist the project to success. What skills they bring, and, if required what skills need to be gained to get the project kicked off.

Milestones will also be decided in the charter. As the project progresses when do we want to measure success? What needs to be done by when and how will it be measured?

SIPOC Diagram

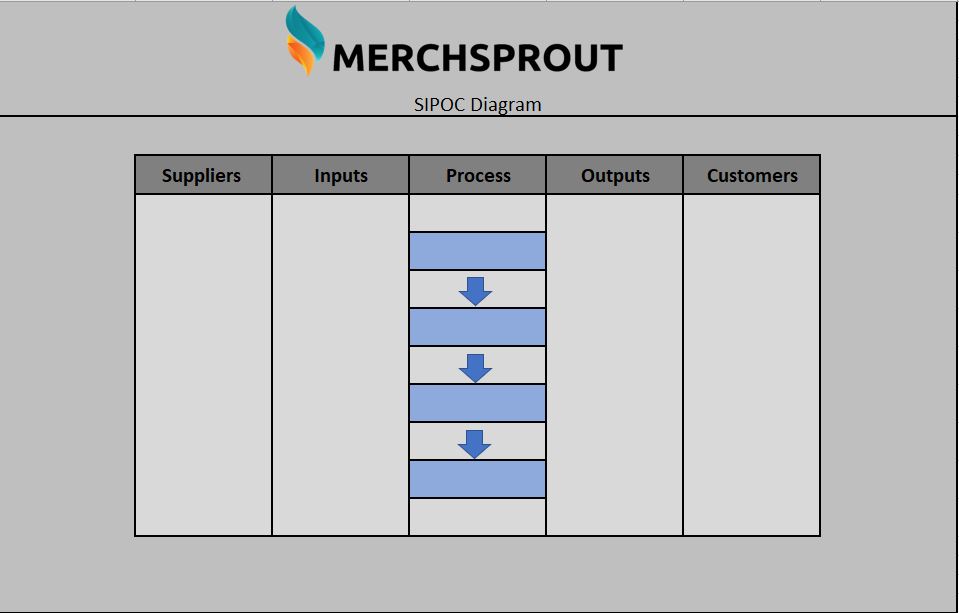

I have included below Merchsprout’s SIPOC table

The SIPOC tool allows users to list out the relevant inputs and outputs of the project.

How do we use it?

This tool documents and communicates the overall scope of process related to the project the contents.

Process

The first thing to start with may sound a little backwards. However, we start in the middle of the process column. Usually, 3-6 major steps are documented here.

Supplier

We then add in the supplier column; the departments or the suppliers who supply the process. Remember, the supplier is not limited to outside vendors and companies. Its any anyone or any department that supplies upstream inputs in the process.

Inputs

List the inputs that go into the process to be transformed. These inputs can be materials, people, items, information or data.

Outputs

These are completed forms or the material that has been completed as a product of the process.

Customer

List the receiver of this output. Again it could be people department or companies that receive what the output churns out.

Do you need help finding that needle in the haystack?

The only 100% sure-fire way to ensure you are dealing with quality in Chinese factories is to have someone on the ground, on your side. Batting for your team. A team player who not only knows how to capture and report out but a player that can hold those suppliers to account in the event of quality issues.

Here at Merchsprout, we do just that, we offer you the ability to save time and money by doing the hard work for you. We offer several services that allow you to remotely oversee operations.

If you want to learn more about how we do what we do and the services we offer, have a look here.

Source Chinese Products Without Going China

If you want to just get in touch, we are a friendly bunch and honestly just like hearing from you. Contact us below, or leave a comment.

Dealing Remotely Is Very Much A Possibility, Have The Right Team Members On Your Side

Source Chinese Products Without Going to China is not only a possibility it’s relatively easy when you have the right team on your side. We are the right team for Sourcing, Auditing and Quality control.